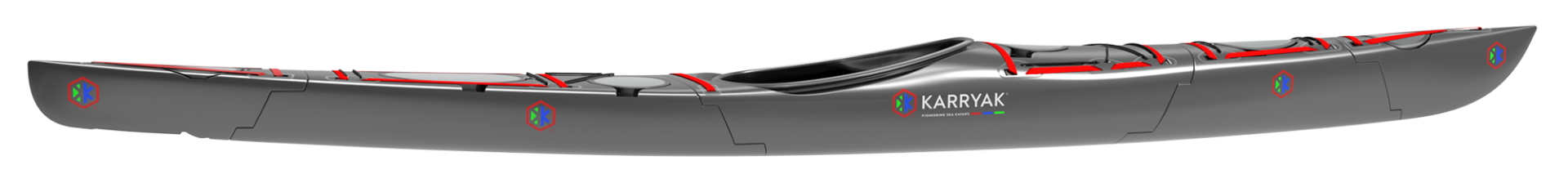

KARRYAK® Pioneering Sea Kayak is the first modular, carbon fibre, sea kayak, designed and built as a set of monocoque sections for strength and ease of handling, and is a step change in design, functionality, and user experience with an array of innovative features.

KARRYAK® was born out of a simple desire to make a performance, composite, comfortable, sea kayak that could be easily and safely carried, transported, and stored.

KARRYAK® Pioneering Sea Kayaks are specifically designed for world-wide travel.

Every sea kayaker might recognise some (or all?) of the following?

Composite one-piece sea kayaks are awkward to carry due to their size, shape, and weight.

Transporting one-piece sea kayaks on vehicles is a feat of physics and engineering, or real potential for accidents and injury, or just physically impossible.

Storing composite sea kayaks, and keeping them safe when not being paddled, presents issues for many paddlers, and potential paddlers, alike.

Air travel with a bicycle works well for adventures around the world, but with a sea kayak it is nigh on impossible.

Composite sea kayaks have almost all been made the same way for the last 50 years or so; joining a hull and deck, adding a cockpit rim, drilling holes for fittings, bolting and bonding things on, often to a non-structural surface or laminate.

For 50 years composite sea kayaks have also been made with frustrating features, such as deck fittings that break, hatch rims that pull off, cockpit rims not set square and that trap fingers, or that are sharp & shred spraydecks.

There are numerous issues with skeg sliders that jam, skeg wires that kink, skeg boxes that break or leak, rudders exposed on landing or when towing and rudder up-hauls hidden behind the paddler.

Add to this the thin deck lines that hurt to hold and can’t be used to carry kayaks for fear of breaking the fitting, and hatch lids that either implode or get pulled off due to surf or sun.

Then consider cockpits that hold so much water the kayak is almost impossible to paddle after self-rescue, raw edges in the cockpit that shred your shins, and a seat that is so uncomfortable and can’t be properly customised.

And as sea kayaks are regularly heated by sun and cooled by seawater, expanding and contracting the air trapped inside, there surely had to be a way to allow hatches and bulkheads to breathe, without drilling a hole in the bulkheads?

The KARRYAK® design brief – build the sea kayak commensurate with our vision, minimum compromise and maximum innovation and fun:

- Design and build a modular, performance, sea kayak

- Use monocoque principals to create best strength to weight ratio

- Re-imagine the features and fittings of a sea kayak

- Develop a sea kayak for world-wide travel

- And make it comfortable!

Must have qualities

- Light, easy to carry, transport and store

- Strong build, capable of touring, surfing, and playing

- Skeg or rudder, or neither, or in combination

- Suits a wide range of paddler body shapes and sizes

- Paddles in all respects as a one-piece sea kayak

- Comfortable, and a delight to paddle

Steve Macfarlane

Innovator and Patent Holder

Steve was running a sea kayaking business on the west coast of Scotland, where time on the water was increasingly occupied considering ‘sea kayaking into old age’ and ‘how to transport a sea kayak off the water’.

He looked at other sports, like cycling, sailing, and F1 and it was clear they all had one thing in common; they had embraced manufacturing with pre-impregnated carbon-fibre and an autoclave to reduce weight and simultaneously increase strength.

This led to defining ‘the big 3’ requirements:

- Modular sea kayak, for ease of transport

- Reliable skeg/rudder system

- Robust hatches and lid system

It was another step to re-imagining a sea kayak from end to end, making it as light, strong, comfortable, functional and above all, easy to carry and transport as possible.

The result is KARRYAK® Pioneering Sea Kayaks.

Modular, monocoque sea kayak

KARRYAK® is built in modular sections for ease of carrying and transporting, and once assembled is a high-performance sea kayak and touring-kayak

A KARRYAK® has an outstanding strength to weight ratio due to its carbon-fibre monocoque sections

The patented KARRYAK® joint reduces the stress and shock loads passing between sections by managing their divergent dispersal.

KARRYAK® is the first modular, pre-impregnated (pre-preg), carbon-fibre, performance, transportable sea kayak, designed and built as a set of monocoque sections.

Reliable skeg/rudder system

There’s also the age-old argument of rudder-v-skeg-v-none, so why not build a sea kayak that has all three options?

KARRYAK® patented footrest system and control blade provides all three operating modes in one.

Control cords run internally, and there’s no need for a manual rudder uphaul or manual skeg slider as it’s all operated by foot.

The KARRYAK® control blade system has a pull-pull mechanism that both raises and lowers the control blade for skeg deployment and control, as well as steering in the rudder function.

The control blade is housed in the tail section and operates as both an adjustable skeg when initially deployed, and a rudder when fully deployed to vertical.

Robust hatch and lid system

KARRYAK® patented hatches are carbon fibre, flush to the deck surface, strong, won’t blow off or suck in, and stay attached and sealed in all conditions.

Hatch lids are all egg-shaped and use a patented principle, for both sealing and retaining, by using hidden O rings.

All 6 hatch lids together only weigh just over 1kg, and they float.

Compensation valves ensure equalised pressure to enable removal and manage the expansion and contraction of trapped air.